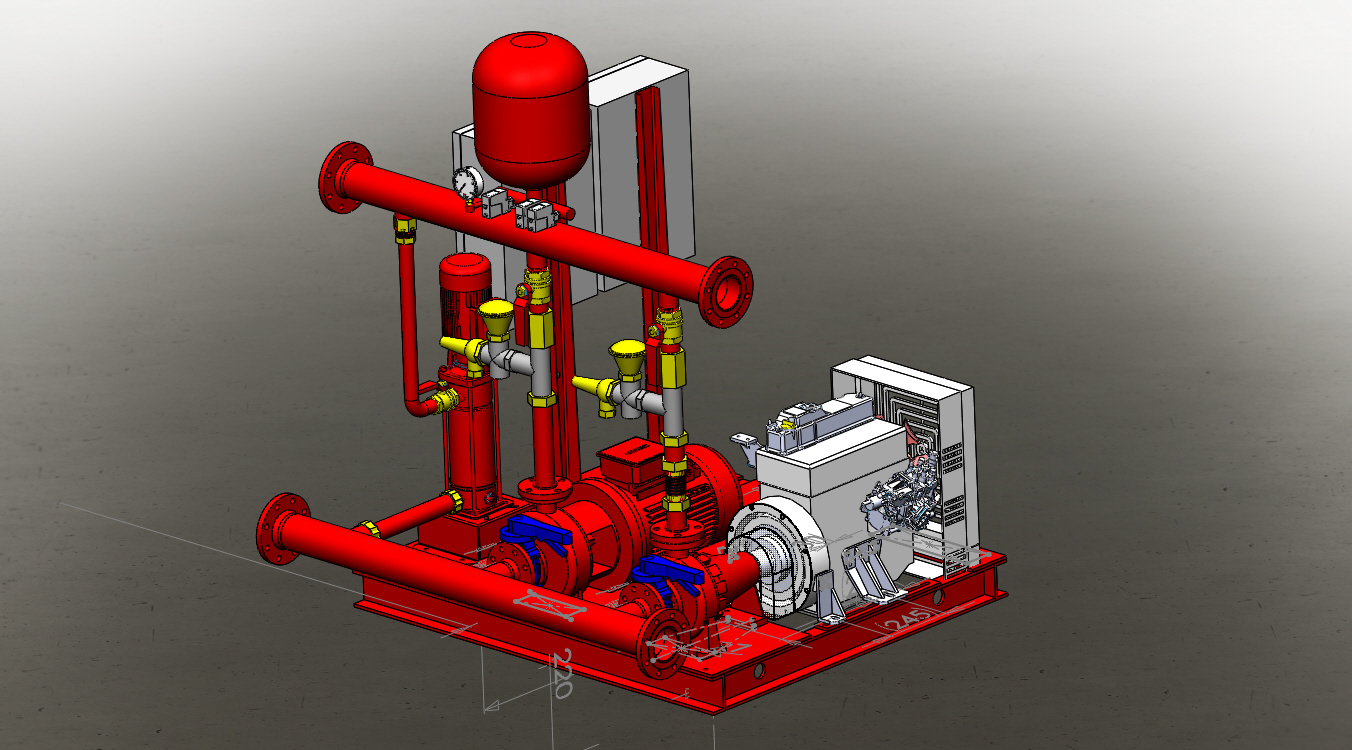

PUMPING GROUPS

Our lifestyle is based on the quality and durability of our products, providing customers with the pump system that best suits their needs and requirements.

Innovation, responsibility, security and trust are values that the customer can find in each of the CMC Fire Solutions products and services.

We have a team that works daily to adapt and learn about the technological advances of firefighting equipment, to satisfy the needs and requirements of customers, aligning our efforts in the development of future trends, thus ensuring resistance to the onslaught of time.

Pumps:

All of our pumps and aggregates are produced by a group of professionals using advanced systems of laser cutting technology, press brakes and state-of-the-art collecting trays. All metal parts have a high precision anti-corrosion coating.

Prior to installation, our professionals carry out a study of the needs, requirements, application and practical guidelines of the pump equipment to be purchased, in order to offer you the most appropriate from our stock. Whether multi-stage, different materials and shaft couplings, they all have one thing in common, they are built to high quality standards and have been tested in a strictly defined testing program.

Base frame:

The construction of shape and tension optimized base benches assembled in modules for diesel or electric aggregates guarantee unrivaled torsional strength thanks to generously dimensioned parts, wall thickness, optimized geometry and additional stiffness. Likewise, our benches have a proven and planet-friendly coating that provides high-quality anti-corrosion.

Due to the construction of the bench in modular systems, the assembly allows different combinations of aggregates, since each screwed connection unit even allows the connection between 2 drip tray units in a single unit.

Engines:

Regardless of the customer’s selection of diesel or electric motors, we always use reliable drives as we work with the best suppliers and specialists in order to always have the most suitable for each application.

The transmissions will depend on the needs of the customer, and they can choose between classic flanges and shaft couplings.

Similarly, we have different types of spray pumps (pedestal or bearing) that have easy-maintenance designs and interchangeable wear rings. All have standard materials (cast iron) and depending on the pump requirements the materials may vary, such as completely CC480 K or its version in stainless steel. All have VdS approval

Independent mechanical seals are used to facilitate shaft maintenance.

We have diesel and electric spray pumps. The sprinkler pumps are built with three-phase motors according to IEC standards in protection class IP55.

Likewise, the electrical units have very compact couplings that do not require maintenance, they can also be fitted with extension couplings on request. These robust couplings successfully avoid serious dangers. On the other hand, for diesel aggregates, CMC Fire Solutions offers performances from 29 kW to 290 kW. All aggregates are standard equipped with a tank size coordinated with a special drip tray. In the case of separate aggregates, the fuel tank will be placed independently in any other place in the space provided for the pumping system.

RD type series:

The base frames are specially designed so that the consoles required for the tube set can be screwed directly on. Therefore, there is no difference in axle height, frame size, or base attachment. This type allows high safety in the design of the sprinkler control center.

Diesel control cabinets meet all VdS requirements. On the basis of high safety requirements, only high-quality and durable products are installed.

Auxiliary units:

Jockey pumps, they are container filling pumps, compressors for ventilation of pressurized air water tanks or to maintain the pressure of dry networks are available in many different variations and combinations.

Frequency controlled pressure maintenance pump:

Frequency control systems have a wide advantage compared to the classical system. The slide operation will preserve the pump and piping system. The design is much simpler as the entire electronics are combined with the engine clamps within a box directly on the engine.

» Fire-Boost » booster stations for hydrant systems:

The new «Fire-Boost» booster stations are specially manufactured for the field of fire fighting. They are available with direct or indirect connection to the drinking water supply as a single or double pump in a completely redundant version. Furthermore, the intelligent modular design makes it possible to respond to the special needs of customers.

The fully automatic stations comply with DIN 14462 and 1988 standards.

Booster stations for above ground and underground hydrants:

If large quantities of water are needed for supplying underground or above-ground hydrants, the well-known standard pumps come into play. These pumping groups can be equipped with the control for hydrant systems specially designed for the requirements of DIN 14462.

Accessories:

To ensure the fully reliable operation of diesel engine spray pumps, CMC Fire Solutions offers a wide range of ventilation components adapted to the circumstances of the installation site, all perfectly coordinated with the selected diesel engine.

Likewise, the client has at their disposal different exhaust systems, all suitable, coordinated and in perfect symmetry with the needs of each client.